Isicelo se-Quote

I-Wire Mesh iwumkhiqizo owenziwe efekthri odalwe ngokuhlangana kwentambo ecwebezelayo ehlanganisiwe futhi yalukwa ukuze yakhe izikhala ezifanayo ezihambisanayo ezinezikhala ezilinganayo.Ziningi izinto ezisetshenziswayo ekwenzeni i-wire mesh, noma kunjalo, izinto ezinkulu ngokuvamile zivela ezinsimbi.Zihlanganisa: insimbi enekhabhoni ephansi, insimbi enekhabhoni ephezulu, ithusi, i-aluminium, ne-nickel.

Imisebenzi emikhulu ye-wire mesh ukuhlukanisa, ukuhlola, ukumisa, nokuvikela.Amasevisi noma imisebenzi ehlinzekwa yi-wire mesh noma indwangu yocingo inenzuzo emkhakheni wezolimo, wezokuthutha wezimboni, kanye nezimayini.I-wire mesh yakhelwe ukunyakaza kwemikhiqizo eyinqwaba nezimpushana ngenxa yamandla nokuqina kwayo.

Abakhiqizi bakhiqiza i-wire mesh ngokusebenzisa izindlela ezimbili-ukuluka nokushisela.

Ukweluka kuhilela ukusetshenziswa kwezinsimbi zezimboni, ikakhulukazi ama-rapier looms.Abakhiqizi bangase basebenzise indwangu yokweluka impahla ukuze baluke inetha lamaphethini amaningi ahlukene ajwayelekile nangokwezifiso.Uma sebeqedile, abakhiqizi balayisha i-mesh kuma-rolls, abawanqamule futhi bawasebenzise uma kudingeka.Abhekisela ezintanjeni ezilukwe zivundlile, noma ngobude, njengezintambo ezijikayo, nezintambo ezilukwe ziqonde phezulu, noma eziphambanayo, njengezintambo zokuluka.

Ukushisela kuyinqubo lapho abasebenzi bensimbi bebopha izintambo ngogesi ezindaweni lapho bephambana khona.Abasebenza ngensimbi baqedela imikhiqizo ye-wire mesh eshiselwe ngokuyisika nokuyigoba ibe yisimo.I-Welding idala i-mesh enamandla futhi engakwazi ukuqaqa noma ukuhlukana.

Izinhlobo ze-Wire Mesh

Kunezinhlobo eziningana ze-wire mesh.Ahlukaniswa ngokwendlela ezakhiwe ngayo, izimfanelo/umsebenzi wazo kanye nephethini yokuluka.

Izinhlobo zocingo ezinezintambo eziqanjwe ngokwakhiwa kwazo kanye/noma izimfanelo zifaka: Izintambo zocingo ezishiselwe, ezinezintambo zikathayela, ezinezikhala zocingo ezinamekwe nge-PVC, amagridi ensimbi eshiselwe kanye nensimbi engenasici.

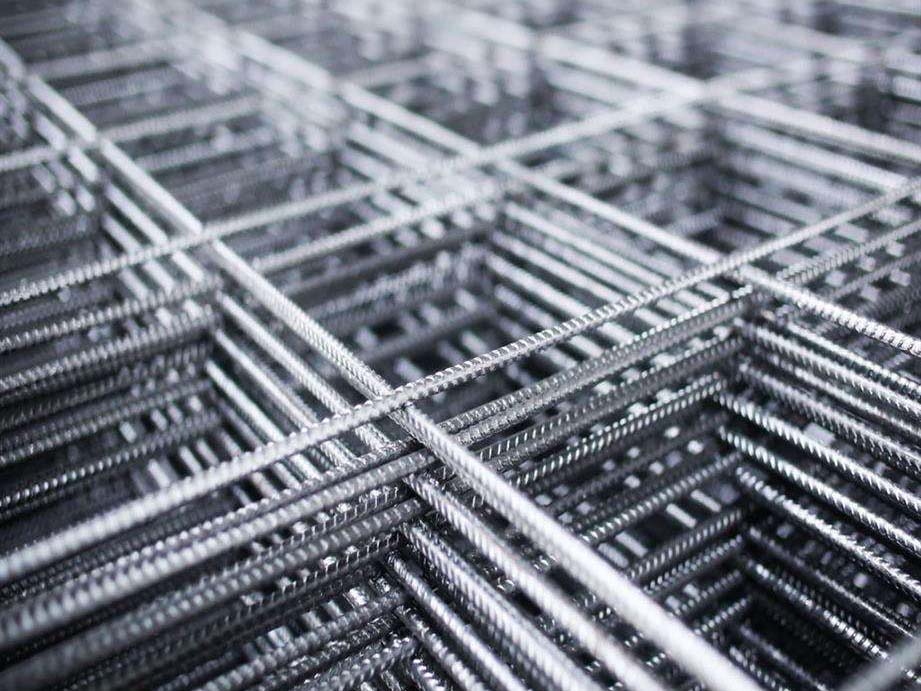

I-Welded Wire Mesh

Abakhiqizi benza lolu hlobo lwe-mesh ngentambo enephethini eyisikwele.Ngokuyishisela nge-elekthronikhi, benza i-mesh enamandla kakhulu.Imikhiqizo ye-wire mesh eshiselwe ilungele ukusetshenziswa okuhlanganisa: ucingo lokuvikela lapho kudingeka khona ukubonakala, ukugcinwa kanye nokuqoshwa ezindaweni zokugcina impahla, amalokha okugcina, izindawo zokugcina izilwane emitholampilo yezilwane kanye nezindawo zokukhosela izilwane, ukuhlukaniswa kwamakamelo okusebenzayo kanye nezicupho zezinambuzane.

I-wire mesh eshiselwe isebenza kahle kakhulu kulezi zinhlelo zokusebenza ngoba 1), iqinile futhi izomelana nezinselele zemvelo njengomoya nemvula, 2) izobambelela ngokuqinile endaweni, futhi 3) ingenziwa ngendlela oyifisayo kakhulu.Uma abakhiqizi benza i-wire mesh eshiselwe ngensimbi engagqwali, ihlala isikhathi eside nakakhulu.

I-galvanized Wire Mesh

Abakhiqizi benza i-galvanized wire mesh besebenzisa i-plain noma i-carbon steel wire abayinika amandla.I-galvanization inqubo lapho abakhiqizi befaka khona i-zinc enamathela ensimbi yocingo.Lolu ngqimba lwezinki njengesihlangu esigcina ukugqwala nokugqwala kungalimazi insimbi.

I-galvanized wire mesh ingumkhiqizo oguquguqukayo;lokhu kuyiqiniso ikakhulukazi ngoba itholakala kuzo zombili izinhlobo ezilukiwe nezishiselwe.Ngaphezu kwalokho, abakhiqizi bangenza imikhiqizo ye-mesh wire mesh esebenzisa ububanzi obubanzi bezintambo nosayizi wokuvula.

Abakhiqizi bangase baqinise izintambo zocingo ngemva kokuzenza, noma bangase baqinise izintambo ngazinye bese bezenza zibe yimanetha.I-galvanizing wire mesh ngemva kokuba sebeyenzile ingase ikubize imali eyengeziwe ekuqaleni, kodwa ngokuvamile iveza imiphumela yekhwalithi ephezulu.Noma kunjalo, i-galvanized wire mesh ngokuvamile iyathengeka.

Amakhasimende athenga i-galvanized wire mesh yezinhlelo zokusebenza ezingenakubalwa, ezinye zazo ezihlanganisa: uthango, ezolimo nengadi, i-greenhouse, i-architecture, ibhilidi nokwakha, ukuphepha, onogada bamafasitela, ama-infill panel, nokunye okuningi.

I-PVC Coated Welded Mesh

Njengoba igama layo libonisa, abakhiqizi bamboza i-PVC enezintambo ezishiselwe nge-PVC (i-polyvinyl chloride).I-PVC yinto yokwenziwa ye-thermoplastic eyenziwe lapho abakhiqizi bepholisa i-vinyl chloride powder.Umsebenzi wayo ukuvikela izintambo ezigugulekayo ukuze iqine futhi yelule ukuphila kwayo.

Ukufakwa kwe-PVC kuphephile, akubizi uma kuqhathaniswa, akuvikeli ukushisa, amelana nokugqwala, futhi kuqinile.Futhi, iyakwamukela ukwenza umbala, ngakho-ke abakhiqizi bangenza ukukhiqiza i-PVC inameshi enamathekisthi kuyo yomibili imibala ejwayelekile nengokwezifiso.

PVC camera anezikhala ashiselwe ithandwa amakhasimende nge anhlobonhlobo izicelo.Iningi lezinhlelo zayo, nokho, zisendaweni yokubiya, ngoba isebenza kahle ngaphandle.Izibonelo zalokhu kubiyelwa kwezilwane zifaka: ukubiyelwa kwezilwane nezindawo ezivalekile, ukubiyela izingadi, uthango lokuvikela, udonga lomgwaqo onguthelawayeka, ukugada umkhumbi, uthango lwenkundla yethenisi, nokunye nokunye.

Ibha Yensimbi Eshiselwe

Ama-grating ensimbi ensimbi eshiselwe, eyaziwa nangokuthi ama-grate ensimbi ashiselwe, ayimikhiqizo ehlala isikhathi eside kakhulu futhi eqinile ye-wire mesh.Afaka izimbobo eziningi ezihambisanayo, ezinezikhala ezilinganayo.Lezi zimbobo ngokuvamile zisesimweni sonxande abade.Bazuza amandla abo ekwakhekeni kwensimbi nokwakhiwa okushiselwe.

Amagreyidi ensimbi eshiselwe umkhiqizo wezintambo ezinezintambo ezikhethwayo ezisetshenziswayo ezinjengalezi: ukuchithwa komgwaqo, ukwakhiwa kwezindonga zokuphepha, imisele yamanzi esiphepho, izakhiwo, izindlela zokuhamba zabahamba ngezinyawo, ukufakwa phansi kwethrafikhi esetshenziswa kancane/ibhuloho, ama-mezzanines nezinye izinhlelo zokusebenza ezingenakubalwa zokuthwala imithwalo.

Ukuze kuhlangatshezwane nemithetho nezimfuneko zalezi zinhlelo zokusebenza, abakhiqizi bashisela le mikhiqizo ngogqinsi oluhlukahlukene kanye nokuhlukaniswa kwamabha okuzala.

I-Stainless Steel Wire Mesh

Insimbi engenasici inazo zonke izimfanelo ezinhle zocingo enziwe ngalo.Okusho ukuthi, iqinile, imelana nokugqwala, inamandla aqinile.

Insimbi engagqwali inezikhala ingashiselwa noma ilukwe, futhi iguquguquka kakhulu.Nokho, imvamisa amakhasimende athenga i-stainless steel wire mesh ngokusungulwa kokuvikela izindawo ezikhiqiza izimboni.Bangase futhi basebenzise insimbi engagqwali kwezolimo, ingadi nokuphepha, phakathi kwezinye izinhlelo zokusebenza.

Izintambo ezinezintambo ezichazwa ngephethini yazo yokuluka zihlanganisa: ezinezikhala ezidabukile, ezinezikhala eziphindwe kabili, ezinezikhala zokukhiya, ezinezikhala eziphakathi nendawo, ingaphezulu eliyisicaba, ezinezikhala ezilula ezilukwayo, ezinezikhala ze-twill weave, ezinezikhala ze-Dutch weave ne-Dutch twill weave mesh.

Amaphethini we-weave angaba ejwayelekile noma angokwezifiso.Umehluko owodwa oyinhloko kuphethini ye-weave ukuthi i-mesh iboshwe noma cha.Amaphethini e-crimping abakhiqizi be-corrugations bakha ocingweni ngokufa kwe-rotary, ngakho-ke izingxenye ezahlukene zezintambo zingakhiyelana.

Amaphethini we-crimped weave ahlanganisa: i-double weave, i-crimp yokukhiya, i-crimp ephakathi nendawo kanye ne-flat top.

Amaphethini okulukwa angagwegwesi ahlanganisa: i-plain, twill, plain dutch kanye ne-dutch twill.

I-Double Weave Wire Mesh

Insimbi engenasici inazo zonke izimfanelo ezinhle zocingo enziwe ngalo.Okusho ukuthi, iqinile, imelana nokugqwala, inamandla aqinile.

Insimbi engagqwali inezikhala ingashiselwa noma ilukwe, futhi iguquguquka kakhulu.Nokho, imvamisa amakhasimende athenga i-stainless steel wire mesh ngokusungulwa kokuvikela izindawo ezikhiqiza izimboni.Bangase futhi basebenzise insimbi engagqwali kwezolimo, ingadi nokuphepha, phakathi kwezinye izinhlelo zokusebenza.

Izintambo ezinezintambo ezichazwa ngephethini yazo yokuluka zihlanganisa: ezinezikhala ezidabukile, ezinezikhala eziphindwe kabili, ezinezikhala zokukhiya, ezinezikhala eziphakathi nendawo, ingaphezulu eliyisicaba, ezinezikhala ezilula ezilukwayo, ezinezikhala ze-twill weave, ezinezikhala ze-Dutch weave ne-Dutch twill weave mesh.

Amaphethini we-weave angaba ejwayelekile noma angokwezifiso.Umehluko owodwa oyinhloko kuphethini ye-weave ukuthi i-mesh iboshwe noma cha.Amaphethini e-crimping abakhiqizi be-corrugations bakha ocingweni ngokufa kwe-rotary, ngakho-ke izingxenye ezahlukene zezintambo zingakhiyelana.

Amaphethini we-crimped weave ahlanganisa: i-double weave, i-crimp yokukhiya, i-crimp ephakathi nendawo kanye ne-flat top.

Amaphethini okulukwa angagwegwesi ahlanganisa: i-plain, twill, plain dutch kanye ne-dutch twill.

I-Double Weave Wire Mesh

Lolu hlobo lwe-wire mesh luhlanganisa iphethini elandelayo yokuluka eboshwe ngaphambili: Zonke izintambo ezinqamulayo ziyadlula nangaphansi kwezintambo ze-weft.Izintambo ze-warp zigijima futhi ngaphansi kwesethi izintambo ezimbili ze-weft, noma izintambo ezimbili ze-weft, ngaleyo ndlela igama.

I-Double weave wire mesh iqinile kakhulu futhi ilungele ukusekela izinhlelo zokusebenza zokuqina okuhlukahlukene.Isibonelo, amakhasimende asebenzisa imikhiqizo ye-double weave wire mesh kuzinhlelo zokusebenza ezifana nalezi: izikrini ezidlidlizayo zokumbiwa, izikrini ezidlidlizayo zama-crusher, amapulazi ocingo nokulima, izikrini zemigodi yezoso nokunye.

Khiya iCrimp Weave Wire Mesh

Le mikhiqizo ye-wire mesh ifaka izintambo ezicijile ngokujulile.Ama-crimps awo abonakala njengama-knuckles noma ama-bumps.Ziyahambelana ukuze abasebenzisi bakwazi ukuzivalela ngokuqinile endaweni ngokubeka i-crimp eyodwa phezu kwezintambo eziphambanayo.Phakathi kwezimpambanomgwaqo, imikhiqizo ye-crimp mesh yokukhiya inezintambo eziqondile.Ngokuvamile banephethini yokuluka engenalutho.

Amaphethini we-Lock crimp weave anikeza ukuzinza okwengeziwe emikhiqizweni ye-wire mesh efana nama-rack racks, obhasikidi nokunye.

I-Intermediate Crimp Weave Wire Mesh

I-wire mesh enama-crimp amaphakathi, kwesinye isikhathi abizwa ngokuthi “ama-intercrimp,” ifana ne-wire mesh enama-crimp ajulile.Zombili zivumela abasebenzisi ukuthi bakhiye izintambo endaweni.Nokho, zihlukile ngezindlela ezimbalwa.Okokuqala, i-intercrimp wire mesh iba ngothayela, kunokuba iqonde, lapho ingacishwanga khona.Lokhu kwengeza ukuzinza.Futhi, lolu hlobo lwe-wire mesh lumaholoholo futhi lubonakala lubanzi kunezikhala ezivulekile ezijwayelekile.

Abakhiqizi bangakha i-intercrimp wire mesh yezinhlelo zokusebenza ezidinga ukuvuleka okukhulu kunoma iyiphi inombolo yezimboni, kusukela ku-aerospace kuye ezakhiweni.

I-Flat Top Weave Wire Mesh

I-weave ephezulu eyisicaba ifaka izintambo ezingaqinile nezintambo ezicwiliswe ngokujulile.Ndawonye, lezi zintambo zakha i-wire mesh eqinile, evalelekayo enendawo eyisicaba ngaphezulu.

Imikhiqizo ye-Flat top weave wire mesh ayinikezi ukumelana okuningi nokugeleza, okungaba isibaluli esikhangayo kwezinye izinhlelo zokusebenza.Enye yezinhlelo ezivame kakhulu ze-flat top weave ukudala izikrini ezidlidlizayo.Imeshi enale phethini yokulukwa nayo ijwayeleke kakhulu njengesakhi sezakhiwo noma isakhi sesakhiwo.

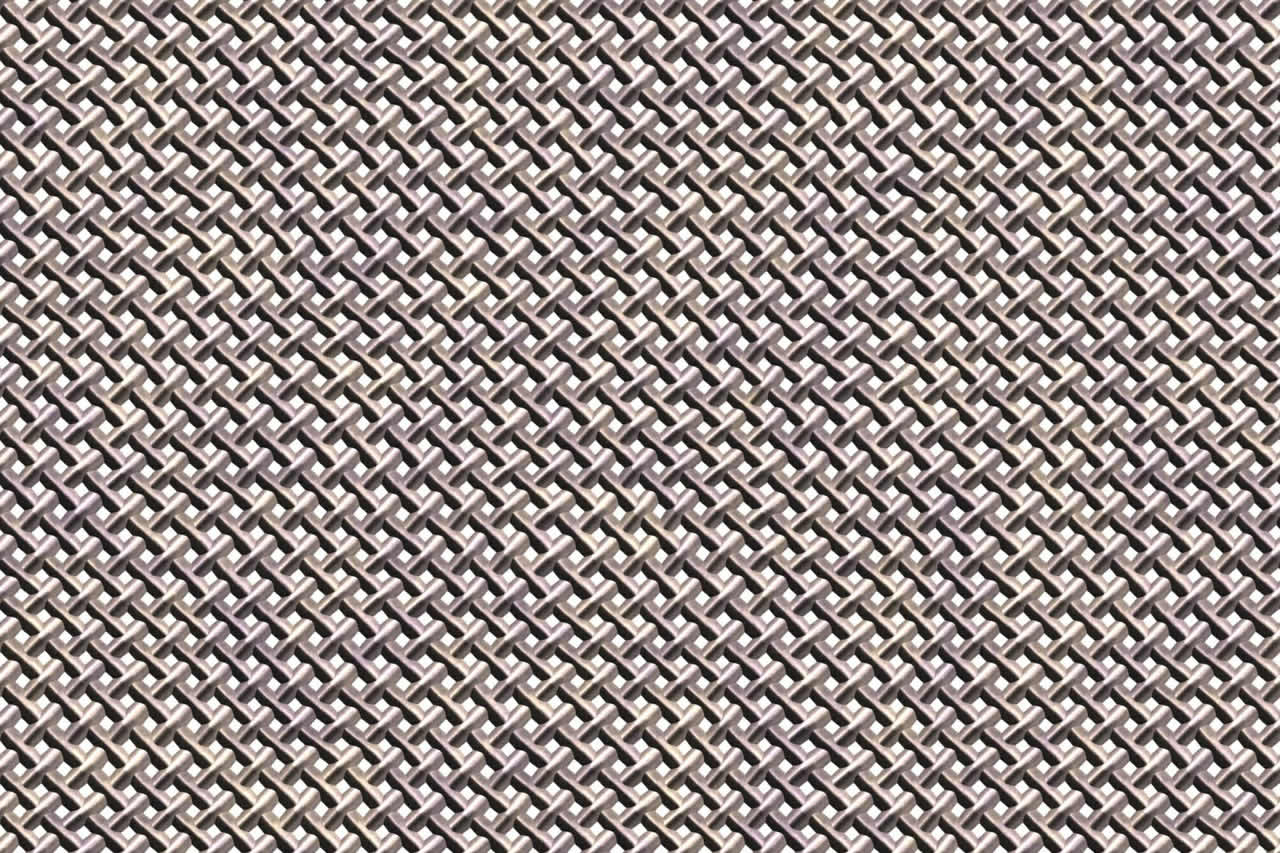

I-Plain Weave Wire Mesh

Iphethini ye-plain weave ihlanganisa izintambo ze-warp ne-weft ezihamba ngapha nangapha kwenye.Imikhiqizo ye-Plain weave mesh iyona ejwayeleke kakhulu kuyo yonke imikhiqizo ye-wire mesh elukiwe.Eqinisweni, cishe yonke inetha engu-3 x 3 noma kancanyana yenziwa kusetshenziswa iphethini ye-plain weave.

Okunye okuvame ukusetshenziswa kwe-plain weave wire mesh ukuhlola.Lokhu kufaka phakathi, ukuhlolwa komnyango wesikrini, izikrini zamawindi nokunye.

I-Twill Weave Wire Mesh

Abasebenza ngensimbi benza iphethini yokuluka ama-twill ngokweluka izintambo eziqondile ngazinye phezu nangaphansi kwezintambo ezimbili ze-weft ngesikhathi.Ngezinye izikhathi, bahlehlisa lokhu, bathumele izintambo ze-weft ngazinye ngapha nangapha kwezintambo ezimbili ezigoqekayo.Lokhu kudala ukubukeka okumangalisayo nokwenyuka kokuqina.Le phethini yokuluka isebenza kahle kakhulu ngezintambo ezinkulu ezinobubanzi.

Amakhasimende ngokuvamile aya e-twilled weave mesh lapho enohlelo oluhlobene nokuhlunga.

I-Plain Dutch Weave Wire Mesh

I-Plain dutch weave wire mesh ihlanganisa i-plain weave ehlanganiswe eduze ngangokunokwenzeka.Ukuminyana kuyisici esiphawulekayo se-Dutch weave.Lapho udala ama-weave ase-Dutch alula, abakhiqizi bangasebenzisa izintambo zamadayamitha ahlukene.Uma lokhu kunjalo, ngokuvamile basebenzisa izintambo ezinkulu ze-warp nezintambo ezincane ze-weft.

Imikhiqizo ye-Plain Dutch weave wire mesh ilungele ukugcinwa kwezinhlayiyana kanye nezinhlelo zokusebenza zokuhlunga ezinhle kakhulu.

I-Dutch Twill Weave Wire Mesh

Iphethini ye-dutch twill weave ihlanganisa iphethini ye-twill nephethini yesi-Dutch.Njenge-standard Dutch weave (plain dutch), i-dutch twill weave isebenzisa izintambo ezinkulu ze-warp kunezintambo ze-weft.Ngokungafani ne-standard twill weave, i-dutch twill weave ayihlanganisi ukwelukwa ngokuphindaphindiwe nangaphansi.Ngokuvamile, esikhundleni salokho ifaka ungqimba oluphindwe kabili lwezintambo ze-weft.

I-Dutch twill weave wire mesh ayinakho ukuvuleka ngoba izintambo zicindezelwa ndawonye eduze kakhulu.Ngenxa yalesi sizathu, benza izihlungi zamanzi ezinhle kakhulu nezihlungi zomoya, becabanga ukuthi noma yiziphi izinhlayiya zincane kakhulu noma azibonakali ngeso lenyama.

Ukusetshenziswa kwe-Wire Mesh

I-Intermediate Crimp Weave Wire Mesh

Izinhlangano zezimboni zisebenzisa i-wire mesh.Zisetshenziswa kakhulu njengodonga lwe-perimeter noma uthango lokuvikeleka.Ezinye izindawo lapho zisetshenziswa khona zihlanganisa:

● Iphansi eliwukhonkolo

● Ukugcina izindonga, insimu, nezisekelo zemigwaqo

● Izikhumulo zezindiza, amagalari, namahubhu

● Imisele namachibi okubhukuda

● Izinto zokwakha esezivele zakhiwe, njengama-stitrups kumakholomu nemishayo.

Izici ze-Wire Mesh

Kulula ukufaka:Izinto ezisetshenziswayo zincishiswa zibe osayizi abahlukahlukene kanye nokuma ukuze zenze amadiski, okwenza isitolimende sibe lula futhi sisheshe.

Ukuthutha kulula:Imeshi yakhelwe ngezinhlaka ezahlukene nobukhulu.Ukuwahambisa endaweni yokufakwa kulula futhi kushibhile, ikakhulukazi kumanetha ensimbi.

Kuqiza kahle:ukusebenziseka kalula kwe-wire mesh kunciphisa ukusebenza ngokusika impahla phakathi, kunciphisa isikhathi nemali kuze kufike ku-20%.

Isikhathi sokuthumela: Mar-17-2022