Request for Quote

Wire Mesh is a factory-made product created from the intertwining of lustrous wire that has been merged and interweaved to form consistent parallel spaces with symmetrical gaps. There are several materials used in making wire mesh, however, the major materials are generally from metals. They include: low-carbon steel, high-carbon steel, copper, aluminum, and nickel.

The major functions of wire mesh are separating, screening, structuring, and shielding. The services or functions offered by a wire mesh or wire cloth is beneficial to the agricultural, industrial transportation, and mining sectors. Wire mesh is designed for the movement of bulk products and powders because of its strength and durability.

Manufacturers produce wire mesh using two methods–weaving and welding.

Weaving involves the use of industrial looms, especially rapier looms. Manufacturers may use the loom to weave mesh of many different standard and custom patterns. When they are done, manufacturers load the mesh onto rolls, which they cut off and use as needed. They refer to wires woven horizontally, or lengthwise, as warp wires, and wires woven vertically, or crosswise, as weft wires.

Welding is a process during which metalworkers electrically bond wires at the points where they intersect. Metalworkers complete welded wire mesh products by cutting and bending them into shape. Welding creates mesh that is strong and that cannot unravel or fall apart.

Types of Wire Mesh

There are several kinds of wire mesh. They are classified according to the way they were made, their qualities/function and weave pattern.

Wire mesh varieties named after their fabrication and/or qualities include: welded wire mesh, galvanized wire mesh, PVC coated welded wire mesh, welded steel bar gratings and stainless steel wire mesh.

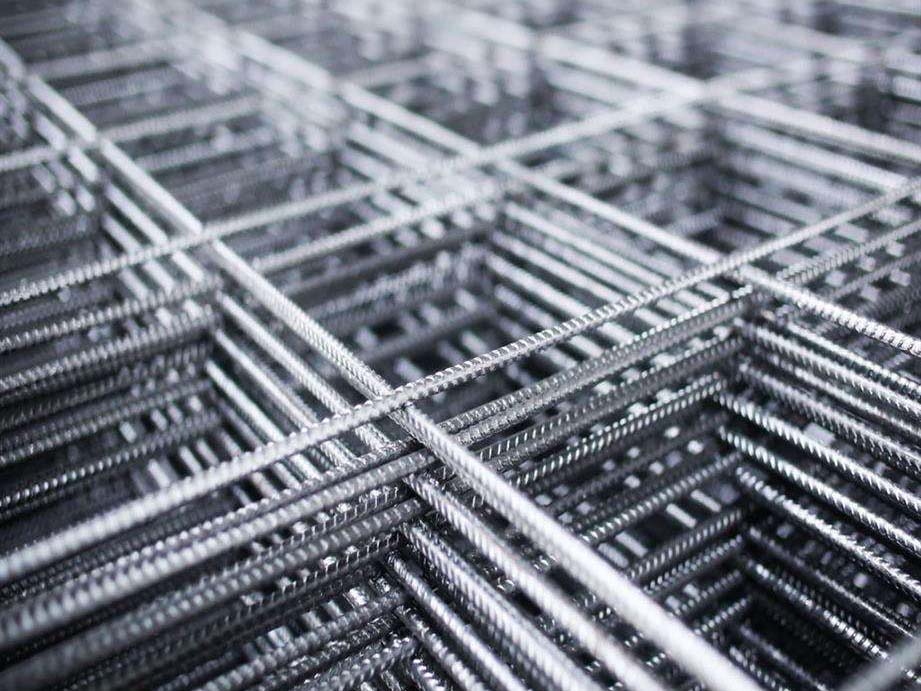

Welded Wire Mesh

Manufacturers make this kind of mesh with square-shaped patterned wire. By welding it electronically, they form a very strong mesh. Welded wire mesh products are perfect for applications including: security fence where visibility is needed, storage and racking in warehouses, storage lockers, animal holding areas in veterinary clinics and animal shelters, practical room division and traps for pests.

Welded wire mesh works so well for these applications because 1), it is durable and will hold up against environmental challenges like wind and rain, 2) it will hold firmly in place, and 3) it is highly customizable. When manufacturers make welded wire mesh from stainless steel, it is even more durable.

Galvanized Wire Mesh

Manufacturers create galvanized wire mesh using plain or carbon steel wire that they galvanize. Galvanization is a process by which manufacturers apply a zinc coating to wire metal. This zinc layer as a shield that keeps rust and corrosion from harming the metal.

Galvanized wire mesh is a versatile product; this is especially true because it is available in both woven and welded varieties. Plus, manufacturers can make galvanized wire mesh products using a wide range of wire diameters and opening sizes.

Manufacturers may galvanize wire mesh after they make it, or they may galvanize the individual wires and then form them into mesh. Galvanizing wire mesh after they’ve already made it may cost you more money initially, but it generally yields higher quality results. Regardless, galvanized wire mesh is usually quite affordable.

Customers purchase galvanized wire mesh for countless applications, some of which include: fencing, agriculture and garden, greenhouse, architecture, building and construction, security, window guards, infill panels, and so much more.

PVC Coated Welded Mesh

As its name indicates, manufacturers cover PVC coated welded wire mesh in PVC (polyvinyl chloride). PVC is a synthetic thermoplastic substance made when manufacturers polymerize vinyl chloride powder. Its job is to shield erosive wire in order to make it stronger and extend its life.

PVC coating is safe, relatively inexpensive, insulative, corrosion resistant, and strong. Also, it is receptive to pigmenting, so manufacturers can make produce PVC coated mesh in both standard and custom colors.

PVC coated welded mesh is popular with customers with a wide range of applications. Most of its applications, though, are in the realm of fencing, since it works so well outdoors. Examples of such fencing include: animal fencing and enclosures, garden fencing, security fencing, freeway guardrailing, ship guardrailing, tennis court fencing, and so on and so forth.

Welded Steel Bar Gratings

Welded steel bar gratings, also known as welded steel bar grates, are extremely durable and strong wire mesh products. They feature a number of parallel, evenly spaced openings. These openings are usually in the shape of long rectangles. They gain their strength from their steel composition and welded construction.

Welded steel bar gratings are the preferred wire mesh product for applications such as: road scrapping, the construction of safety walls, storm drains, buildings, pedestrian walkways, lightly used traffic/bridge flooring, mezzanines and countless other load bearing applications.

To accommodate the regulations and requirements of these applications, manufacturers weld these products with a wide variety of thicknesses and bearing bar spacing.

Stainless Steel Wire Mesh

Stainless steel mesh has all of the favorable qualities of the wire from which it is made. That is to say, it is durable, corrosion resistant, with high tensile strength.

Stainless steel mesh can be welded or woven, and it is extremely versatile. Most often, though, customers purchase stainless steel wire mesh with the invention of safeguarding industrial manufacturing areas. They may also use stainless steel in agriculture, gardening and security, among other applications.

Wire mesh defined by their weave pattern include: crimped mesh, double weave mesh, lock crimp mesh, intermediate crimp mesh, flat top, plain weave mesh, twill weave mesh, plain dutch weave mesh and dutch twill weave mesh.

Weave patterns can be standard or custom. One main distinction in weave pattern is whether or not the mesh is crimped. Crimping patterns are corrugations manufacturers create in the wire with rotary dies, so different segments of wires can lock into one another.

Crimped weave patterns include: double weave, lock crimp, intermediate crimp and flat top.

Non-crimped weave patterns include: plain, twill, plain dutch and dutch twill.

Double Weave Wire Mesh

Stainless steel mesh has all of the favorable qualities of the wire from which it is made. That is to say, it is durable, corrosion resistant, with high tensile strength.

Stainless steel mesh can be welded or woven, and it is extremely versatile. Most often, though, customers purchase stainless steel wire mesh with the invention of safeguarding industrial manufacturing areas. They may also use stainless steel in agriculture, gardening and security, among other applications.

Wire mesh defined by their weave pattern include: crimped mesh, double weave mesh, lock crimp mesh, intermediate crimp mesh, flat top, plain weave mesh, twill weave mesh, plain dutch weave mesh and dutch twill weave mesh.

Weave patterns can be standard or custom. One main distinction in weave pattern is whether or not the mesh is crimped. Crimping patterns are corrugations manufacturers create in the wire with rotary dies, so different segments of wires can lock into one another.

Crimped weave patterns include: double weave, lock crimp, intermediate crimp and flat top.

Non-crimped weave patterns include: plain, twill, plain dutch and dutch twill.

Double Weave Wire Mesh

This type of wire mesh features the following pre-crimped weave pattern: All of the warp wires pass over and under the weft wires. The warp wires run over and under a set two weft wires, or double weft wires, thus the name.

Double weave wire mesh is extra durable and perfect for supporting applications of varying intensity. For example, customers use double weave wire mesh products for applications such as: vibrating screens for mining, vibrating screens for crushers, fences ranching and farming, screens for barbecue pits and more.

Lock Crimp Weave Wire Mesh

These wire mesh products feature deeply crimped wire. Their crimps appear as knuckles or bumps. They correspond to each other so users can tightly lock them into place by placing one crimp over intersecting wires. In between intersections, lock crimp mesh products have straight wires. They usually have a plain weave pattern.

Lock crimp weave patterns offer added stability to wire mesh products like storage racks, baskets and more.

Intermediate Crimp Weave Wire Mesh

Wire mesh with intermediate crimps, sometimes called “intercrimps,” is similar to wire mesh with deep crimps. They both allow users to lock wire into place. However, they are different in a few ways. First, intercrimp wire mesh is corrugated, rather than straight, where it is not crimped. This adds stability. Also, this type of wire mesh is extra coarse and specifically features wider than normal open spaces.

Manufacturers can create intercrimp wire mesh for applications requiring large openings in any number of industries, from aerospace to construction.

Flat Top Weave Wire Mesh

The flat top weave features non-crimped warp wires and deeply crimped weft wires. Together, these wires create sturdy, lockable wire mesh with a flat top surface.

Flat top weave wire mesh products do not offer much resistance to flow, which can be an attractive attribute for some applications. One of the most common applications of the flat top weave is the creation of vibrating screens. Mesh with this weave pattern is also quite common as an architectural element or structural element.

Plain Weave Wire Mesh

A plain weave pattern features warp and weft wires that go over and under one another. Plain weave wire mesh products are the most common of all woven wire mesh products. In fact, almost all mesh that is 3 x 3 or finer is made using the plain weave pattern.

One of the most common uses for plain weave wire mesh is screening. This includes, screen door screening, window screens and more.

Twill Weave Wire Mesh

Metalworkers create a twill weave pattern by weaving individual warp wires over and under two weft wires at a time. Sometimes, they reverse this, sending individual weft wires over and under two warp wires. This creates a staggered look and increased pliability. This weave pattern works best with large diameter wires.

Customers usually go for twilled weave mesh when they have a filtration-related application.

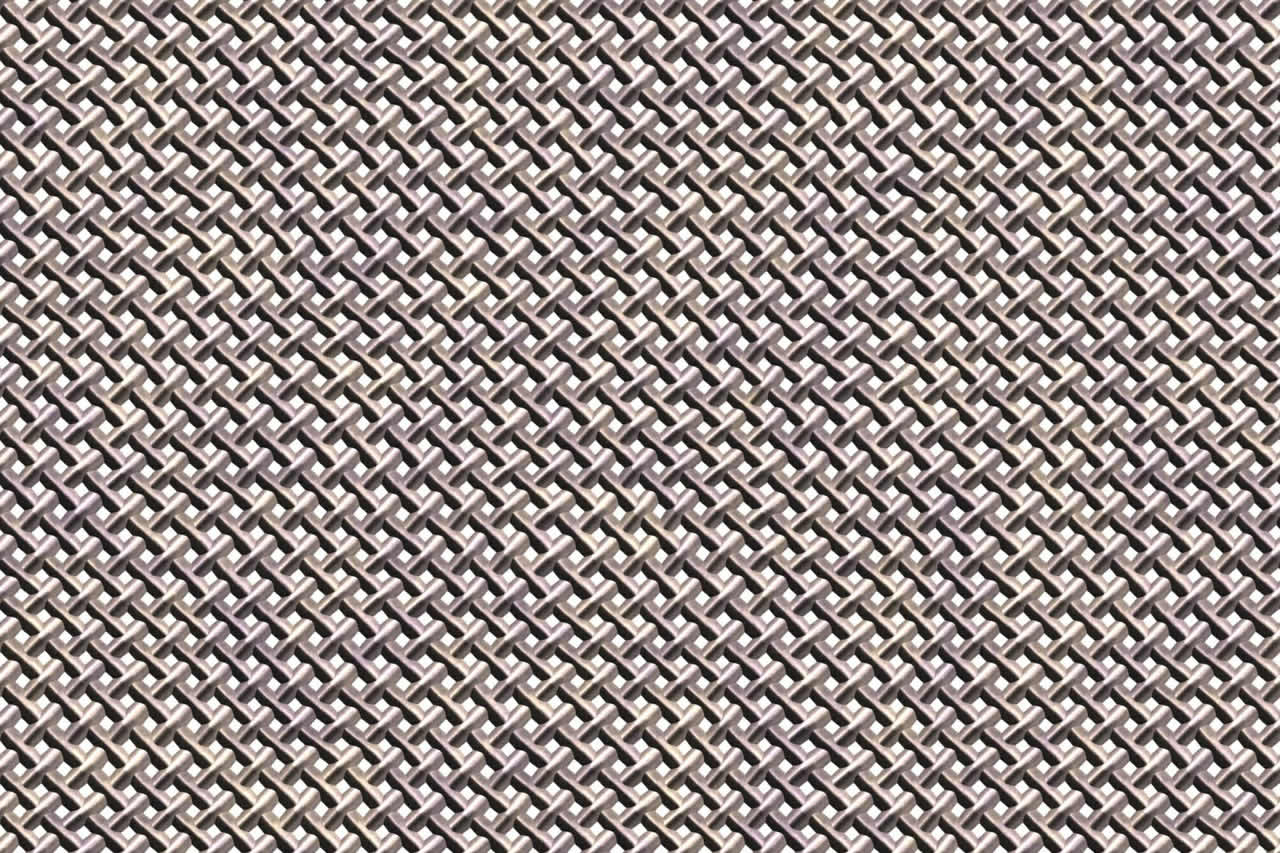

Plain Dutch Weave Wire Mesh

Plain dutch weave wire mesh features a plain weave that has been pushed together as close as possible. Density is a hallmark feature of the dutch weave. When creating plain dutch weaves, manufacturers can use wires of different diameters. When this is the case, they usually use larger warp wires and smaller weft wires.

Plain dutch weave wire mesh products are perfect for particle retention and very fine filtration applications.

Dutch Twill Weave Wire Mesh

The dutch twill weave pattern combines the twill pattern with the dutch pattern. Like the standard dutch weave (plain dutch), the dutch twill weave uses larger warp wires than weft wires. Unlike the standard twill weave, the dutch twill weave does not feature over and under weaving. Usually, it instead features a double layer of weft wires.

Dutch twill weave wire mesh does not have any openings because the wires are pressed together so closely. For this reason, they make excellent water filters and air filters, assuming any particulates are extremely small or invisible to the naked eye.

Uses of Wire Mesh

Intermediate Crimp Weave Wire Mesh

Industrial organizations make use of wire mesh. They are majorly used as a perimeter wall or security fences. Other places where they are used include:

● Concrete floors

● Retaining walls, field, and road foundations

● Airports, galleries, and tunnels

● Canals and swimming pools

● Prefabricated construction elements, such as stirrups in columns and beams.

Features of Wire Mesh

Easy to install: Materials are reduced to various sizes and shapes to form discs, which make installment easy and fast.

Easy to transport: The mesh is designed in a variety of frames and dimensions. Moving them to the place of installation is easy and cheap, especially for steel galvanized mesh.

Cost-effective: the malleability of wire mesh reduces labor by cutting the material in half, reducing time and money down to about 20%.

Post time: Mar-17-2022